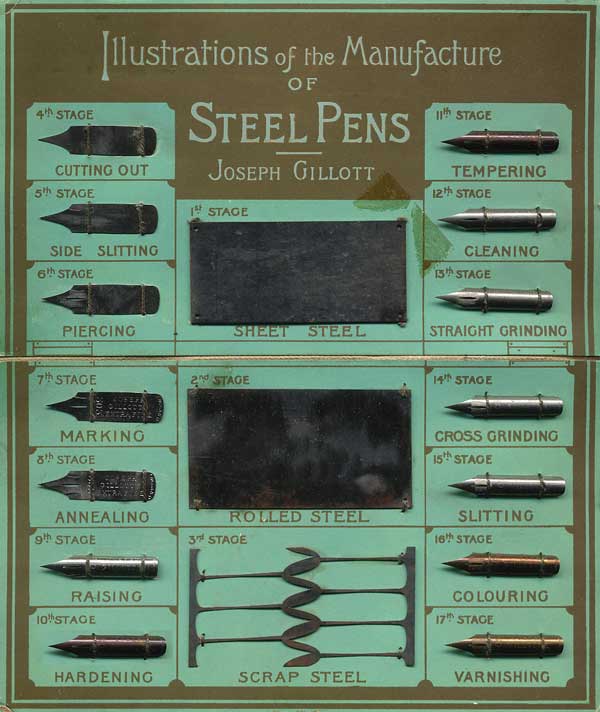

How the vintage Gillott 303 was manufactured

Gillott 303 Salesman’s

Manufacturing Card from the 19th century showing the various steps

in the manufacturing process of the legendary 303 steel pen. Joseph Gillott’s obituary is pasted to the back of this card.

** The following text is taken with

permission from the web site “The History of The

Grove”. The complete text with accompanying images can be viewed at

http://freepages.genealogy.rootsweb.com/~thegrove/giltour.html

The Manufactory in which sheets of steel

are converted into flexible pens is a huge brick building, fronting Graham

Street, at the top of New Hall-hill, so famous in the political annals of

Birmingham for the monster meetings which used to be held there prior to the

passing of the Reform Bill. An idea of the extents of the works may be formed

from the fact that the journey through the various rooms is something like a

quarter of a mile in extent. There are between five and six hundred girls, and

a hundred men and boys employed in the establishment. Three steam-engines of

some sixty horse-power, moreover, are required for the

purposes of the works. We shall endeavor to make the subject comprehensible to

our readers, by noting the process step by step, beginning with sheets of

steel, and tracing the manufacture through all the stages necessary for the

production of the perfect pen.

The steel used is made from the best

Swedish iron, and is brought from

In the cutting-out room is a very

beautiful self-acting machine, which cuts out two pens, and performs four

operations at the same time. There is also in the same room an exquisitely

constructed self-acting machine, invented by two of Mr.Gillott's

sons, Mr. Joseph and Mr.Henry Gillott. This is a

grinding machine, and it performs the two processes of cross and straight

grinding at once. This is one of the most delicate operations in the

manufacture, and the machine does its work in a most effective and perfect

manner. We may add here that the tools for the business are made in this room -

all the things required in the manufactory being made on the premises.

The next operation is what is called

side-slitting; that is, cutting the slit on each side of the pen. It is curious

to see the quickness with which nimble fingers of the girls accomplish this, as

well as all the other parts of their work. With the exception of the two

machines already noticed, which perform more than one operation at a time, each

pen has been dealt with separately, in every stage of the manufacture; and when

we bear in mind the small price at which a box containing a gross of pens can

be bought, the fact that each pen has to pass through the girls' hands

something like a dozen times, not to mention the other processes, it is evident

that it must not linger long with any of them.

After the side-slitting has been done,

the little bit of flat metal which is to form the future pen has to be pierced,

that is to say, the central orifice down which the the

ink flows through the nib has to be made. A self acting machine has been

recently invented, which performs the two operations of side-slitting and

piercing at once, but this has not yet been brought into general use.

Our pen having advanced thus far towards

completion, the next process is that of annealing. It is next passed through a

machine which at once marks the pen with the maker's name, and embosses it with

the trade mark of the firm. During all these processes the future pen is simply

a flat bit of steel, of a shape which merely indicates the future form it is

intended to assume, but still a flat bit of metal with side-slits, the centre

pierced, and marked as described. The next operation is to give the form of a

pen, and this is called raising or binding. The small pens are raised at once,

but the barrel pens require two operations before they are completed. This work

is done as quickly as the other parts of the manufacture. A novel machine has

been invented for this part of the process; a little girl places the pen on a

round, moves the handle of the machine, and it falls into a box raised and

ready for the next stage in it's strange eventful

history.

We next pass to the room where the

half-raised barrel pen is rounded off. The raising process above described only

raises the barrel up to a point where the barrel begins; these half raised

pens, therefore, are next passed through a machine which closes the barrel. And

here we must note a little fact that shows the importance of the annealing

process. Unless this has been done properly, and the metal is of the proper

temper, the barrel will not completely close, and the pen consequently has to

be annealed again.

The next two processes are, perhaps, the

most important and delicate of all. These are called hardening and tempering.

After being raised, the pens are put in boxes, for the purpose of hardening,

and placed in a muffle, and in this state are cast

into a furnace, and subjected to a red heat. From the furnace they are emptied

into pots of oil about five feet deep. The effect of this is to harden them, so

at this stage they are as brittle as glass. After having been submitted to the

oil bath they are put in a cylinder, which being made to revolve rapidly causes

the metal to throw off all the superfluous oil, and renders the pen ready for

the tempering process. It need scarcely be said that in order to make a good

pen a good temper is as necessary as it is to make either a good man or a good

women. But now that it has been baked in a furnace, drowned in oil, and whirled

round to dry, the future pen is found to be most intractable. Its temper is so

bad that at the slightest touch off it flies at a tangent, and goes to pieces

immediately. Nevertheless, the ingenuity of man is too much for the brittleness

of the metal, and he now places the intractable article in a cylinder, and puts

it over a fire, and by nicely graduating the heat destroys the previous

brittleness, gives it the required temper, and turns it out with all the

elasticity requisite for the discharge of its future duties to society.

Both these processes require great

judgment, and much experience in the workmen. On the success of this part of

the work depends, in a great measure, the future quality of the pen, its power

to resist corrosion, its elasticity, as well as its ability to answer the

demand that the `quick and ready writer' may afterwards make upon it. If well

hardened and tempered, as those made by Messrs. Gillott invariably are, the pen

will not unequal to the task imposed upon it, however fluent the ideas of the

scribe may be.

Having been hardened and tempered, it is

necessary that the pen should be cleaned, and this is the next process. To

effect this desirable operation, the pens are placed in a cylinder containing

saw-dust of either beach, box, or pine wood, and emery

powder. The friction produced, as the cylinder revolves, causes the pens to

lose their rough edges, smoothes the points, cleans them, and turns them out

ready for the final operations.

From its dusty, but effective, lavatory

the pen is taken to the grinding-room. This room reminds the visitor of one of

the machine-rooms of the Great Exhibition. It is of enormous length,

and along either side there stretches a line of these grinding machines, in

attending to which more than a hundred girls are employed. The grinding wheels

are coated with emery, and this part of the work is, perhaps, the most delicate

of all; indeed, it requires great skill and experience to perform it properly.

The rapidity, however, with which it is done is not

the least surprising part. Each machine has two wheels; one of these is for

straight grinding, and during this process the pen is held length-wise as it

laid on the wheel for an instant, when the work is done. The other wheel is for

cross-grinding; that is to say, for grinding that part which is to form the

nib; for this purpose the pen is layed cross-wise on

the wheel; then, as before, in the briefest possible twinkling of the grinding

wheel the operation is completed, the machines, at least, two thousand

revolutions in a minute.

We next pass to the slitting- room. Here

the nib is made. The machines which perform this operation have to be very

carefully prepared. Two exceedingly delicate knives are fixed in the press, a

pen is placed in the groove, and the handle of the press pulled, and lo! the slitting is effected with the utmost accuracy. This was

to us one of the most interesting parts of the work. After the slit has been

made you could write with the pen; in fact, the next two operations are

required not so much for utility as for beautifying and making the article

pleasant to look at. The first of these processes is called coloring. After the

pen has been cut, side-slit, pierced, annealed, marked, embossed, raised,

hardened, tempered, cleaned, ground, and slit, it is placed in another

cylinder, and turned slowly over a fire. The operation is performed by hand,

and it requires considerable experience to hit the exact moment when the

desired color is obtained. Different tints are obtained by different degrees of

heat; and it is a very pleasant thing to see the pens assuming various colors

as the cylinder is made gently to revolve. By this simple means every variety

of hue is obtained. The first produced is the well-known bronze; the bright

blue, purple, and other tints are produced by a longer application of heat.

After the coloring operation, the pens are varnished and dried over a stove, to

prevent them form corroding, when they are ready to be put into boxes and sent

into the world to discharge their peaceful mission among men.

We now have the pen complete. But of what

use is the pen without a holder? This is also made in Messrs. Gillott's manufactory. Every process is performed here. In

the yard lies the timber which has been turned into the neat variform holder. This is first cut into pieces of from six

to ten feet in length, and then into slips of the required width and thickness.

These slips are sometimes the width of four, and sometimes seven holders. These

are next passed through a machine, which at first only half completes the work,

but which at the second operation turns the slip out ready for being cut up

into holders of the proper length. This machine is admirably adapted for its

work, and has been patented by Messrs. GILLOTT. They are then passed through a

machine, to mark them, and next taken to the varnishing machine, where, after a

sponge has given the necessary polish, they pass over an endless band to dry -

all these operations being performed with great rapidity. When varnished, they

are cut to the proper lengths by a small circular saw.

The next process is a very interesting

one. The holder, which is now of the length required, but is still only a short

bit of varnished wood, is placed in a self-acting machine, which, at the same

time, rounds off the top end, and clips or presses the other ready for the

reception of the barrel of the pen. The spiral, the serpentine, and other

ornamental designs with which the holders are frequently adorned, are made by a

self-acting machine, through which they are passed; the tube which works the

ornament being a kind of mould that, by the force of the pressure, produces its

pattern on the wood. The machine by which this is done is another admirable

specimen of the inventive skill applied to the various departments of this

manufactory. If a broken holder should get into the tube there is no fear of

accident or injury to the machine; on the slightest irregularity occurring a

spring is touched, which causes the machine to remain inactive until the

impediment is removed.

Both of the last-mentioned processes are effected by self-acting machines, which have only to be

supplied with work, and require no attendance until each job is executed. The

holders are placed in their proper position; then one after another they slide

into the groove, are taken through the machine, and, when finished, are dropped

into a box of exactly their own length; and thus the work goes on and on until

the box is full - each box containing about fifteen gross of holders.

We have now the pen and the holder ready

for each other, and they are now only to be arranged for the market. Some are

placed on cards, but the greater part are sent to the

world in boxes. These boxes are also made on the establishment, and the work is

simple, easy, and pleasant. Every reader is familiar with the many elegant

designs that render some of these boxes so attractive. The mode of manufacture

is, of course, similar to that used in workshops in which such articles alone

are made, and of which a full description will be given in our papers devoted

to that subject. We mention the matter here simply to show the completeness

with which the work is done at the establishment we are now describing.

Before we leave the workshops we must

bear our willing and hearty testimony to the care that is taken of the health

of the persons employed by Messrs. GILLOTT. All the rooms are airy, light,

lofty, well ventilated, and scrupulously clean. The utmost order and decorum

reign everywhere. The girls are neatly and cleanly dressed, and their good

taste is shown in the fact that in every window there are small trees and

flowering plants, which, in the spring, summer, and autumn months, make their

work-rooms almost like gardens for fragrance and beauty. Nothing can exceed the

good effect that such kindly care must have on the workpeople. The sense of the

importance of cleanliness is seen in every department. Even in those in which

oil is used, as in the tempering and in the engineering branches of the business, there is neither stench nor dirt.

We may add here that all the girls are

paid by the piece, and nothing more clearly illustrates the difference in their

capacities than the difference in the amount of their earnings.

Nor should any one quit these works

without spending a little time examining the three large cases of pens in the

warehouse. The cases are covered with glass and in each of them there are

upwards of three thousand pens. The pens are arranged in a very artistic

manner, so as to produce a really pleasant effect. Here are pens of every kind

and description, shape and make, size and color. In one of these cases are

specimens of the largest and the smallest pens that have been ever made. Some

idea of the difference between these extremes may be formed when we mention

that the smallest are just discernible by the naked eye, and that upwards of

three million of these Lilliputian instruments would be required to form the Brobdignagian one that is placed beside them.

It would be unjust were we to close this

brief account of a manufactory which produces upwards of a hundred millions of

pens in the course of each year, without expressing our earnest obligations to

Messrs. GILLOTT for the great readiness with which they permitted us, without

reserve, to witness all the processes, and to inquire into all the mysteries of

their business, or without thanking specially Mr. H. Gilbert and Mr. W. R.

Ward, by whom we were accompanied on our tour of inspection, and who with a

patient anxiety to give us the fullest information, pointed out every part of

the manufacture, even to its minutest detail.